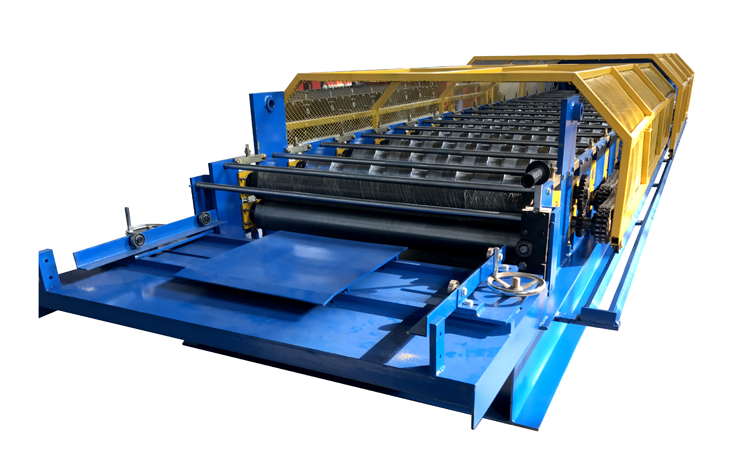

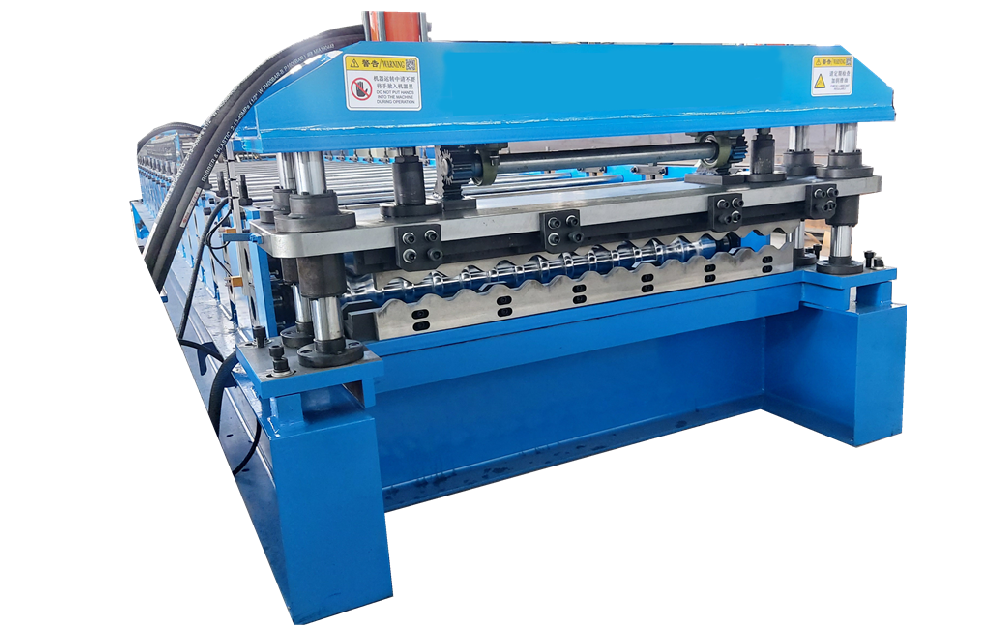

For many newly entered customers only pay attention to the price , ignoring the parts of the machine.In fact, many parts of the roll forming machine are crucial, affecting the finished beauty of the material.Our shearing are bolted with standard parts, which is convenient for replacement and maintenance after a long time of use.

Corrugated sheet roofing machine,there are two kinds of shearing mechanism,electric cutter and hydraulic cutter.There is not much difference between the two different shearing mechanism, but the function is suitable for different regions, so we can offer optional purchases to our customers.The following is an introduction to the shearing mechanism of corrugated metal roofing sheet machine.

Electric shearing is controlled by a motor,is used in extremely cold areas. Because cold weather will not stop the motor from working.The cold weather and low temperature, so the hydraulic oil in the oil tank of the hydraulic station will solidify, thus affecting the working efficiency of the hydraulic station.Therefore,hydraulic cutter is more widely used than the electric cutter.The hydraulic cutter divided into guide pillar structure and channel steel structure.The cutter with four guide pillars has higher accuracy, longer service life and higher relative price than the cutter with two guide pillars.The shearing mechanism material we use is CR12.Cutter with channel steel structure has a long service life and is not easy to wear in a long time.

English

English اللغة العربية

اللغة العربية