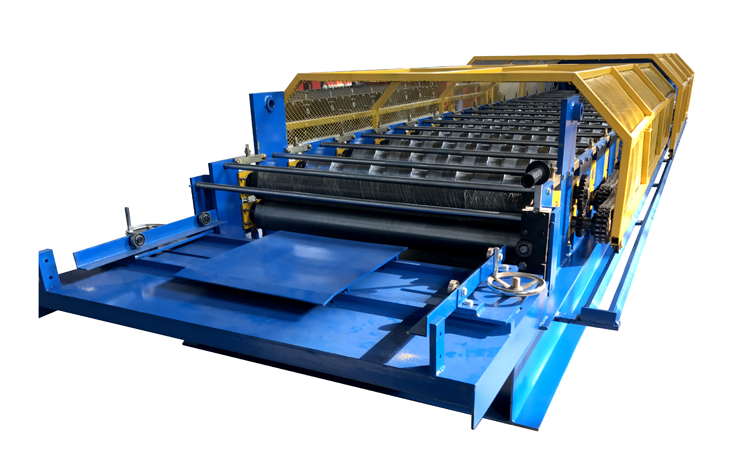

A double layer forming machine has two layers or two levels of roll forming parts, which gives it another name of double level forming machine, and because this machine produces two metal sheets.

A Double Layer IBR Steel Roofing Sheet Roll Forming Machine generally consists of an uncoiler, two infeed guides with optional infeed shear, two roll forming systems, a cutting frame with two cutting dies (a hydraulic press will be equipped as long as this sheet forming machine double level is designed to produce glazed metal tiles), a transmission system, a control system and offset tables. Hydraulic decoiler and automatic stacking machine are optional for this double layer forming machine according to requirements.

Sometimes when a customer needs to produce two different metal sheets, siding, trapezoidal sheets, corrugated sheets or metal tiles, a panel rib and ag panel double layer machine always comes to mind.

English

English اللغة العربية

اللغة العربية