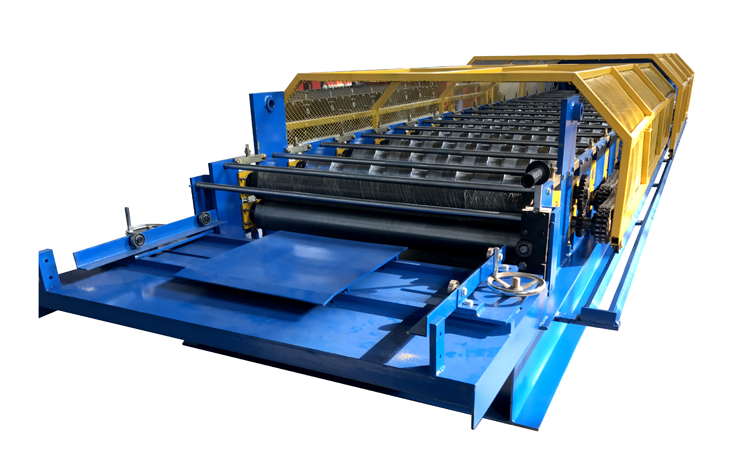

Several parts of Glazed Tile Roofing Former Machine are composed.

Glazed Tile Roll Forming Machine is divided into three parts, roller forming part, pressure type part, cutting knife part. The roller forming part of Glazed roof tile steel roll forming machine is dragged by the motor, and the chain drives the rollers to rotate. The pressure part of Glazed tile roofing sheet machine is a hydraulic cylinder that drives the mold up and down, which can press the color steel into many knots, resembling a glazed tile.

The cutter part of Glazed Tile roofing sheet Making Machine is a hydraulic cylinder that drives the tool up and down, which can cut off the colored steel tile. The production process of Glazed Tile Roll Forming Machine is as follows: the colored steel plate enters the roller table forming part, and after molding, it is pressed into an equal distance section by section, and the cutting knife is responsible for cutting the length Glazed roof tile steel roll forming machine control introduction The executive part has a frequency converter drive motor, a hydraulic station motor, two hydraulic solenoid valves of the pressure type, and two hydraulic solenoid valves of the cutting knife.

The detection part of Glazed roofing tile roll forming equipment is: pulse encoder for detecting the length of colored steel tiles, pressure type up and down stroke switch, cutter up and down stroke switch, pressure type up and down operation button, cutter up and down stroke button, emergency stop switch, hydraulic start-stop switch and so on.

English

English اللغة العربية

اللغة العربية