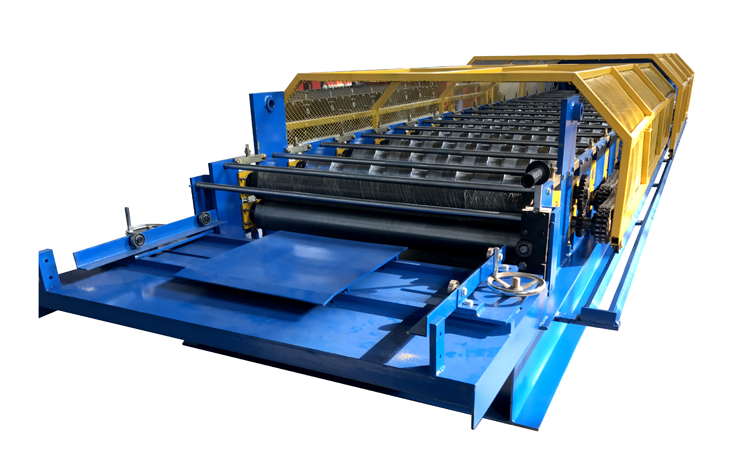

As we know, the color roofing sheets was formed by roofing sheets roll forming machine. A good designed roll forming machine will make the output roofing panels with very beautiful profile and appearance. Therefore, it is a common sense the forming unit is a core part of the roll forming line. However, do you know that a good feeding inlet will enhance the performance of roll forming unit.

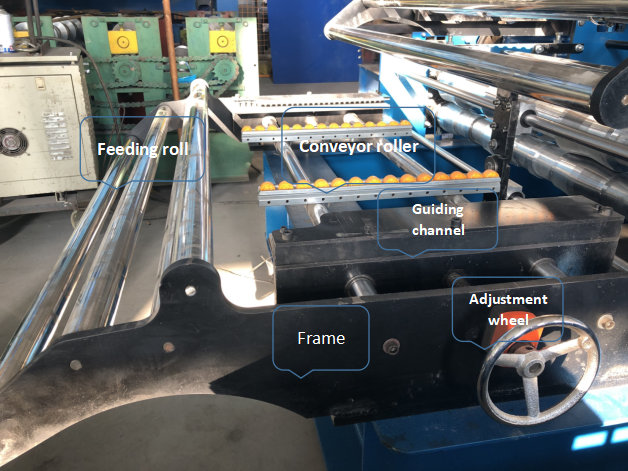

Our new designed feeding inlet is consist of feeding rolls, structure frame, guiding channels and two or three lines of conveyor rollers. They are set up as a complete device to make the coils be fed smoothly and correctly onto its position. How it works?

1, Feeding rolls

You see at the forefront, there are several feeding rolls which are made of stainless steel pipe. They are of quite polishing surface, and each roll is turnable. When coil passes by, it never scratches the surface paint coating of coil.

2, Structure frame

It is made of a integral steel plate by laser cutting. You can’t find any welding joint on this frame. In this way, it be of better physical properties than kind of welded frame. It’s more durable with longer service life.

3, Conveyor rollers

Two or three lines of PP rollers are used to replace steel plate as feeding platform. Compared with the old conventional steel plate, there will ever never cause big friction when cols pass onto the rollers as all the rollers are turnable, they rotate accompany with the coil moving. In this case the surface paint coating is not easy to be scratched.

4, Guiding channel

Each side of the feeding inlet is assembled with a guiding channel. In which a nylon plate and a line of chain type rollers is set up. The nylon plate is more soft than steel so that when coil passes by inside of the channel it protects the coil. As well as the chain type rollers protect the edge of coil though when the channels push the coil tightly from side to center. Each guiding channel is adjusted to move left or right why the adjustment wheel. In this way, they fix the position of coil to make its center match up with the center line of roll forming unit, specially with moulding rollers It also prevents the coil from route deviation.

Thanks to all the new designs, our roll forming machine not only makes wonderful roofing sheets but also protect and save material for roofing sheets manufactures. That is what we do and what we will do. In the future, some other new designs may come up to help our clients achieve a better and easier production work

English

English اللغة العربية

اللغة العربية