Some comments on learning Floor deck roof forming machine

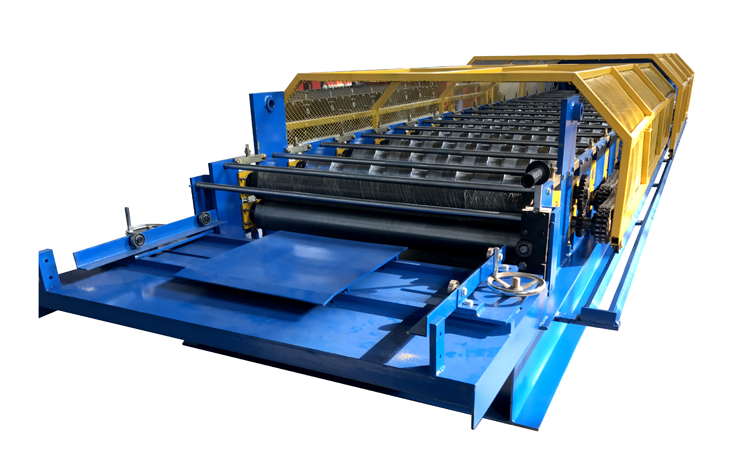

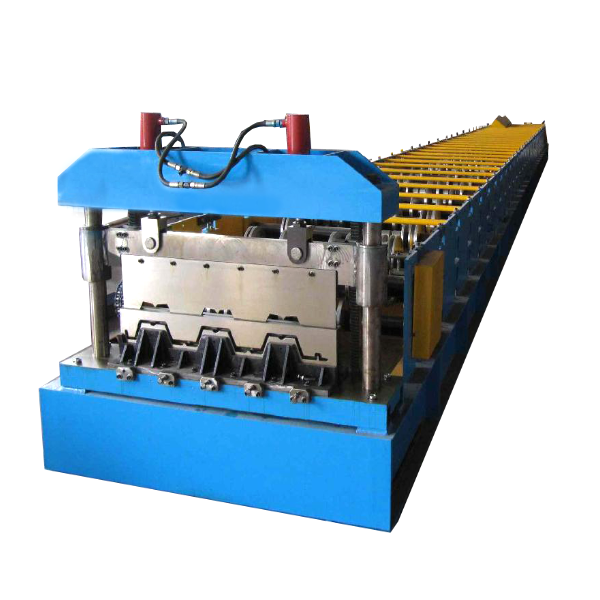

The Floor deck roof forming machine generally uses a double-edged knife. The PLC control cabinet generally chooses Delta and the counter Omron. (You can also choose a specific brand according to customer needs), the solenoid valve of the hydraulic station chooses a large valve, which is not easy to block. The discharge table is divided into simple receiving table and automatic stacker, and the standard configuration is simple. In terms of details, such as painting treatment, sprocket, tile box, pull plate, etc., all parts must be painted before assembly, and then painted as a whole. Then there is the glazed tile machine. Its basic process is similar to that of the trapezoidal tile forming machine, with one more stepped profiling device. In response to the problems of speed, waste and inaccurate pitch raised by customers, we have also solved this problem through continuous research and development. Finally, I talked about the floor deck machine. The thickness of its raw materials is generally 0.8-1.5. It mainly serves as a partition and is mainly used for steel structure buildings. The forming method is mainly split forming to ensure that the front, middle and back of the profile are consistent.

English

English اللغة العربية

اللغة العربية