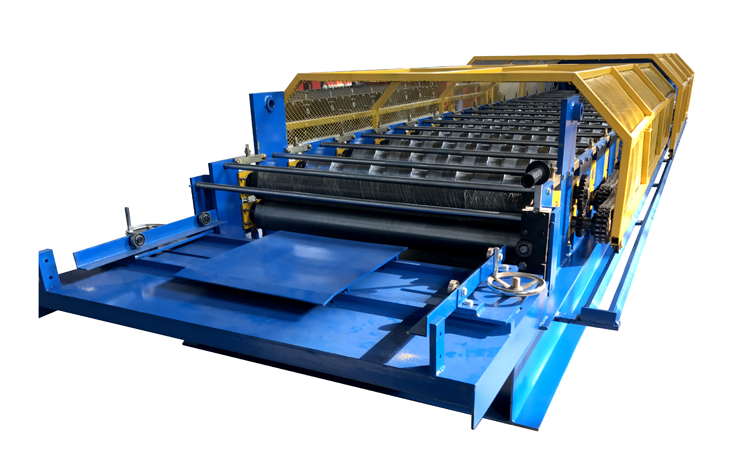

The glazed tile pressing machine is divided into three parts: roll forming part, pressing part and cutter part. The forming part of the roller table is driven by a motor, and the chain drives the roller to rotate. The pressing part is a hydraulic cylinder that drives the mold to move up and down, which can press the colored steel into many knots, like glazed tiles. The cutter part is driven by a hydraulic cylinder to move the cutter up and down to cut the color steel tile. The production process of the step tile roll forming machine is: the color steel plate enters the roll forming part, and after forming, it is pressed to the stepping part and pressed into equal intervals one by one. The cutting machine is responsible for cutting to length.

Bamboo glazed tiles are easy to install, energy-saving and environmentally friendly. Compared with ordinary ceramic tile construction, it greatly shortens the construction time and reduces the construction cost. Because this ceramic tile does not contain any materials, it can be recycled, saving resources in the later demolition. Antique bamboo glazed tile is a kind of color coated steel plate, which is cold-rolled into various corrugated profiles. It is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure roofs, walls and interior and exterior wall decorations. It has the characteristics of light weight, high strength, rich colors, convenient and quick construction, etc., anti-seismic, fireproof, rainproof, long life and maintenance-free. The streamlined glazed tile version, beautiful and generous, special paint, rich in color, classic and elegant, adds beauty to your building. The products produced by the bamboo glazed tile press are light in weight, high in strength, large in bearing capacity, and good in seismic performance. They are widely used in the field of multi-layer steel structure buildings.

If you’d like to ask for a step tile roll making machine, welcome to contact us.

English

English اللغة العربية

اللغة العربية