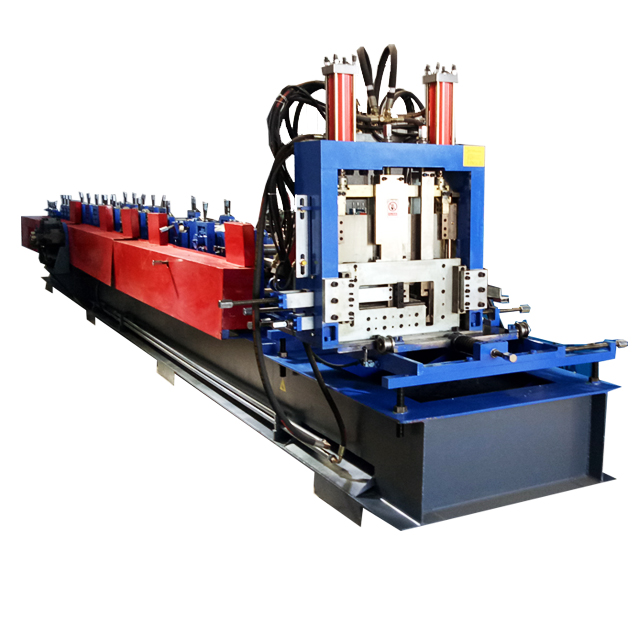

The C-shaped steel tile press is different from the glass tile press. It is hydraulically driven and has a large power, generally around 22KW. It is similar to a shearing machine and a bending machine.

Generally, the control process is complicated, and PLC control is mostly used. C-shaped steel tile press process: the strip is fed from the back of the equipment, presses into the C-shaped steel press through each pressure roller, and is sent out from the machine head. In the traditional process, the C-shaped steel needs to be manually cut to a fixed length after being compressed, and then transported to the punching equipment for punching according to the size required by the customer. The production cannot be continuous and the efficiency is not high. Through the gradual improvement of the production process, the entire process is finally automated and controlled, which greatly improves the production efficiency and increases the technical content and added value of the customer's equipment. The complete automation control system of the C-shaped steel machine equipment adopts a highly integrated network, which makes the performance of the automation system more superior.

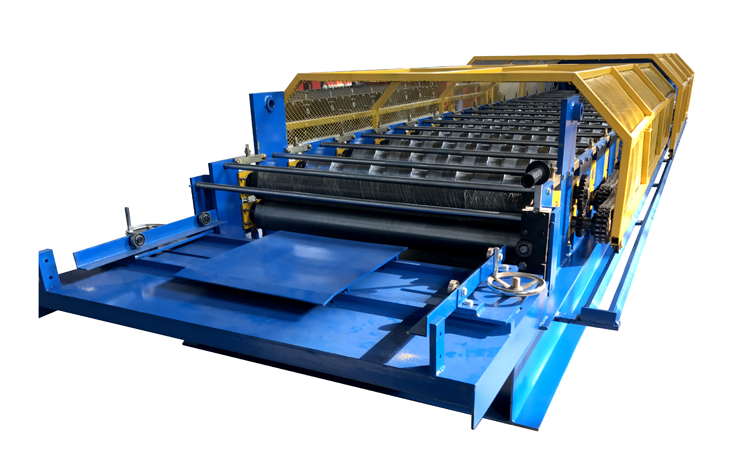

The color steel tile equipment also has operation and maintenance. The color steel tile equipment adopts advanced automatic control software to realize production information management. The entire unit automation control system adopts a highly integrated network to improve the performance of the automation system. The superior color steel tile equipment also has the advantages of operation, maintenance, maintenance, mechanical debugging, and convenient mold replacement.

English

English اللغة العربية

اللغة العربية