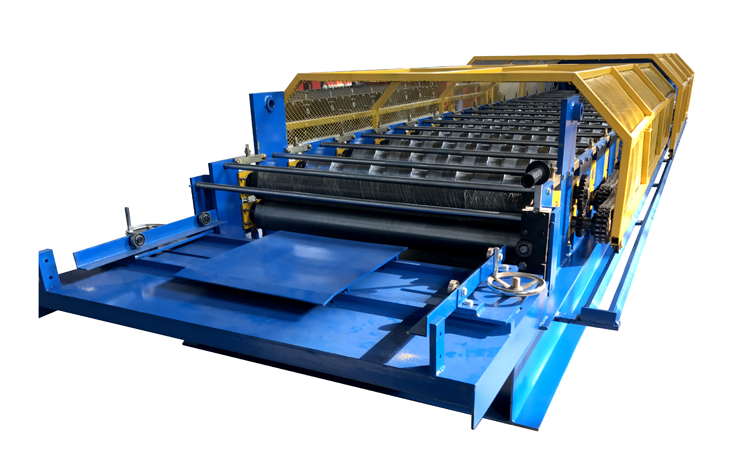

A Roll forming machine use multiple stations to bend metal at room temperature. In these stations, fixed rollers, both guide the metal and perform the necessary bending. When the metal raw material through the bending forming machine, each set of rollers bends the metal more than the rollers at the previous station.

This progressive metal bending method ensures that the correct cross-sectional configuration is obtained while maintaining the cross-sectional area of the workpiece. Normally operating at speed of 30 to 600 feet per minute, roll forming machines are ideal for manufacturing large numbers of parts or extra-long parts.

Roll forming machinery are also suitable for manufacturing precision parts that hardly require finishing. In most cases, depending on the material being molded, the final product has an excellent finish and very fine details.

We are manufacturer of all kinds of cold roll forming machine, our main machines include CZ purlin roll forming machine and roof sheet wall panel roll forming machine. If you want to know the details of the working flow of the machine, please contact with us any time.

English

English اللغة العربية

اللغة العربية