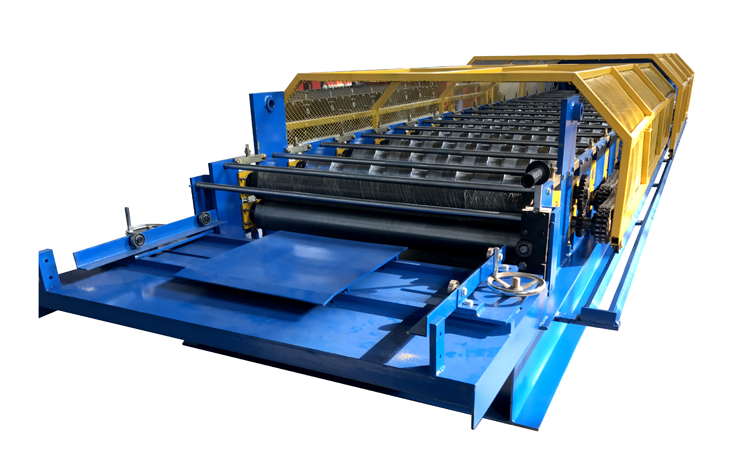

HIGH-QUALITY GLAZED ROOF TILE ROLL FORMING MACHINE DESIGNED

Generally a regular glazed tile roll forming machine works at speed 0-5m/min. But, this roll forming machine can make step roofing tiles at speed up to 8m/min.

For most of projects, there is no need to use gear-box transmission step roof tile roll former. It’s about 40% as expensive as a regular step tile roll former. In some cases, when we have large amount orders of step tiles or metal glazed roofing tiles, we need high-speed machine to ensure the capacity and stable production.

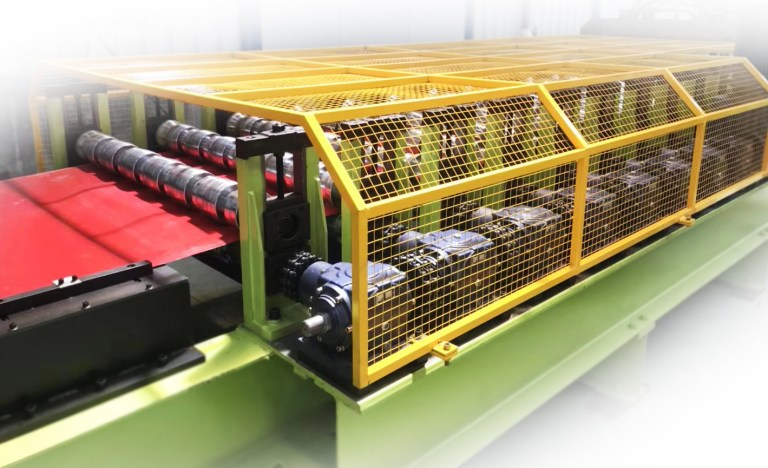

Despite of different designs, this European-quality glazed roof tile roll forming machine has the same components as a regular metal roof tile machine does. Main components are decoiler, feeding guide, roll former, transmission unit, cutting unit, hydraulic unit, PLC control unit and exit tables.

Technical Parameters of this Glazed Roof Tile Roll Forming Machine

Uncoiler/Decoiler: Manual type

Raw Material: Colorbond Steel Coil; Prepainted steel coil;

Material thickness: 0.3mm-0.6mm

Material width: 1250mm

Weight of coil: ≤ 5 mt

Roll Forming stations: 16 tations

Roller Diameter: 76mm

Roller material: 45# steel, coated with 0.05mm thickness hard chrome

Main motor power: 5.5kw

Hydraulic power: 5.5kw

Material of Pressing die: Cr12 steel;

Material of Cutting Die: Cr12 steel;

Tolerance: 1.5mm

Forming speed: 0-8m/min

Control system: Siemens PLC with touch screen

Power supply: 380V/50HZ/3 phase

Approx dimensions: 8900mm x 1500mm x1500mm

GEIT (ZTRFM) can provide all kinds of roll forming machines

English

English اللغة العربية

اللغة العربية