With the development of the Internet, the number of online sales personnel continues to increase, and customers have a wide range of inquiries about choosing roofing sheet machines on the Internet. Many customers do not know which one to buy when purchasing tile pressing machines, and various manufacturers say that their equipment is great, but customer does not know how to judge the quality of the equipment or which manufacturer to choose for purchase. The following are some points that buyers and users should consider when choosing tile pressing machines:

This starts with the selection of accessories and the assembly level of workers for the production of tile pressing machines. The selection of accessories determines the service life of the machine, and the manufacturing process and assembly level also determine the quality of the tile pressing machine. The selected accessories combined with the manufacturing process will ensure stable equipment quality. Experienced and skilled assembly technicians can assemble the machine to ensure that the connection and fastening of each component are just right.

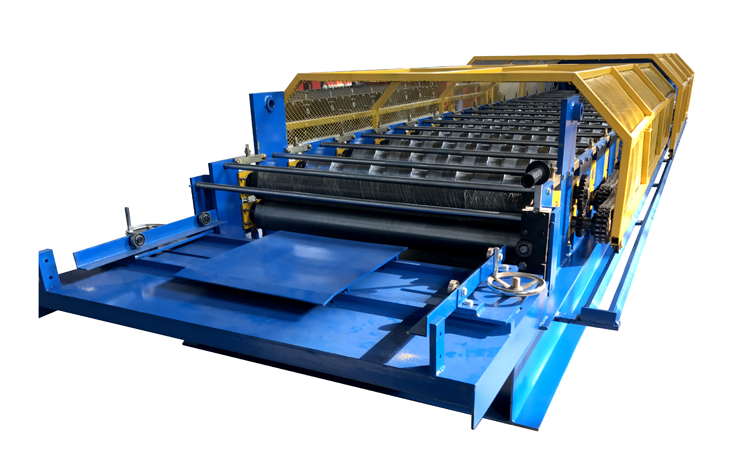

Furthermore, it depends on whether the company provides some protective measures for customers to choose, such as collision prevention devices and friction reduction devices. These devices can protect the products made by machines from damage. Take our company’s guide feeding device for example, there are chains or rollers in device to reduce sheet damage caused by friction.

Whether the machine has high work efficiency, whether the parts are not easily damaged, and whether the machine packaging process is careful are all factors that need to be carefully compared before purchasing the machine. The Geit Group brings the concept of “time is money, quality is life” into the mind of every employee.If you don't know how to purchase a good cold roll forming machines, our company is your best choice.

English

English اللغة العربية

اللغة العربية