General Industry Tech Hebei Developing Co.,Ltd is a comprehensive enterprise integrating scientific research, development, production, sales and service. GEIT Group is a very professional manufacturer and exporter, involved in the design, development and production of various roll forming machines. Our company has cooperative relations with several production factories and joint ventures. Geit Group can manufacture Trapezoidal (IBR) Roofing Sheet Machine,Glazed tile roofing sheet machine,Double layer roofing sheet machine,etc. These machine can manufacture high-quality, high-density color steel tile sheet. As we know, steel roof/ wall sheet is widely used in large span factory building, warehouse, office buildings, villas, roof, cold storage, air purification room, stores, kiosks, and temporary housing.

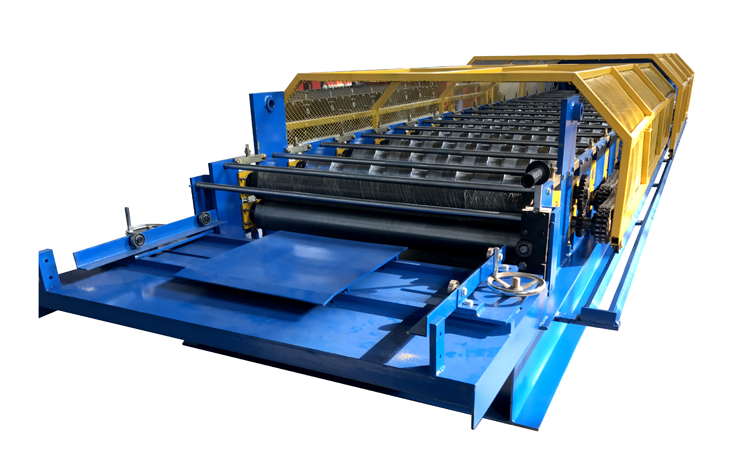

Now let me introduce one of the product--Trapezoidal (IBR) Roofing Sheet Machine. This kind of machine has mainly six part: Decoiler System, Main Roll Forming System, Hydraulic Station, Electric Control System, Shearing Mechanism and Products Receiving Table. Decoiler System is used to unfold the coil to ensure the precision and quality of the coil during processing. And then guide and feeding device will help the material stay smooth and maintain a constant speed. Then material will be transported to the Main Roll Forming System. It is the main part of this machine. It sets several rollers aimed to form the coil sheet into trapezoidal roofing sheet. Hydraulic Station provides the power for the Shearing System. And then you can control the forward and backward movement of the machine and set the length of the sheet through the Electric Control System.Cut the sheet into a fixed length as you set with Shearing Mechanism and finally you can collect the finished product through Products Receiving Table.

On the premise of strictly controlling the quality, at the same time, improve the production efficiency, shorten the delivery time, and ensure that customers can complete the orders on time, in quality and quantity. All the machines we produce need to be tested before leaving the factory. We will never send defective equipment to customers to ensure that the pictures and videos are consistent with the machine you will receive.

English

English اللغة العربية

اللغة العربية