What is “ROLL FORMING MACHINE” ?

Roll Forming machine, also named “Roll Former“, which is a flexible and continuous process, where both the normal rules and the exceptions utilized. It has proved several times that the roll forming machine accomplish roll forming tasks which even seemingly impossible. Although it may take a longer time and much more money. On the other hand, it also showed that plans to roll form simple shapes can create disastrous results. If the designer don’t follow the basic rules of roll forming.

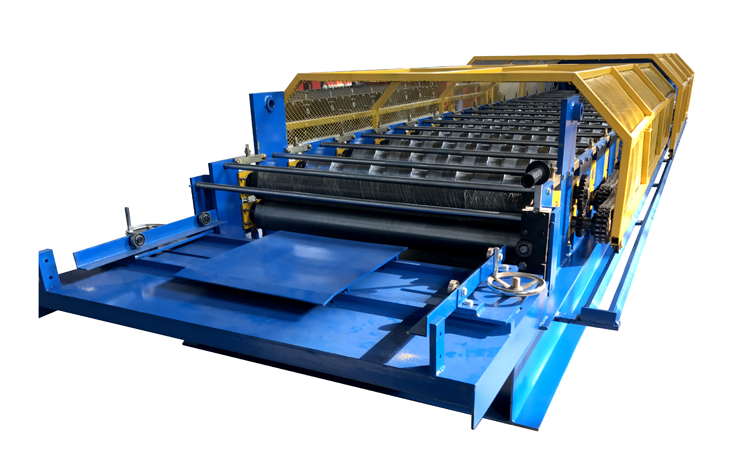

ROLL FORMING MACHINE COMPONENTS

– DECOILER: Used to hold or support steel coils/rolls

– ROLL FORMER: It’s the core of roll forming system, forming the final shapes of sheet.

— MACHINE BASE: Usually welded by H-Beam steel or U-Channel steel. All the rolling tools, motors and transmission system installed on it.

— STANDS: There are generally Integrated Stands, welded with Steel Plate; Chrome-coated Individual Stands, and Cast-iron Individual Stands.

—SHAFTS: All shafts MTC provides are solid shafts where rollers and bearings are mounted.

— TRANSMISSION SYSTEM: Chain-sprockets Transmission; Gear-boxes Transmission; Worm-Gear

— ROLLING TOOLS: Different materials like metal, rubber, TPE etc are common materials for fabricating rolling tools according to different products to make.

– CUTOFF UNIT:. Roll Forming Machine always require an unit to cutoff the coil strips of products into length. And the position can be ahead of the roll forming mill, between the roll forming stands, or after roll forming mill.

– DIES: The punching, notching, mitering and other operations have the same press structures. While design the roll forming machine, we would considering 2 types of dies: Stationary die, which is solidly assembled on the mills base and Flying Die, which can slide on narrow rails. while cutting, notching, punching, the rollformer still works.

– HYDRAULIC SYSTEM: Most of roll forming machines need hydraulic system to provide power for cutoff, punching and pressing, and even driving main roll formers.

– CONTROL SYSTEM: If the roll former is the heart of roll forming system, the control will work as the brain. PLC computer control system is at this moment the best option for roll forming machine control.

English

English اللغة العربية

اللغة العربية