Steel Deck Roll Forming Machine

Material: Steel

Material Thickness: 0.7-1.2mm

Main roll forming machine Power: 15KW*2sets

Motor: Siemens

Material: Steel

Material Thickness: 0.7-1.2mm

Main roll forming machine Power: 15KW*2sets

Motor: Siemens

Steel Deck Roll Forming Machine

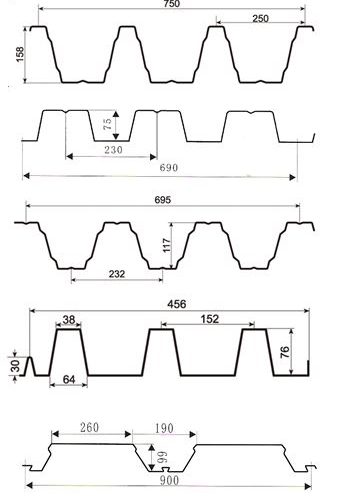

In short,Roof decking floor profiles are typically used as the structural component. The steel decking floor is a cold-formed steel sheet. Metal Decking use in roof and floor systems for supporting the concrete or insulating membrane of a roof. Its design and construction magnify properties of the steel. It causes to create a high strength-to-weight ratio that lowers the material, handling, and erection costs.In addition to, Steel Floor decking roll forming machine This is the new type we engineer for decking machine, used for building surface panel. Metal Deck Roll Forming Machine is a modern, pre-eminent solution for concrete floor work.

Closed Floor Decking Machine

Accordingly, Steel Deck Flooring has a uniform quality that has been an attractive look, especially with the use of properly specified shop and field applied coatings.Lastly, many benefits of steel deck floor such as strength, weight, economy, cost-effective building materials available, the structural strength of the steel deck, relative to its light weight and shear strength,and versatility, recyclable content and, structural performance and ease of installation caused steel deck is ideal for building material for architects also building owners, and engineers.However, The steel deck sheets used for roofs and floors. they support gravity loads between the joists and beams. decking machine including uncoiler and, coil sheet equipment, roll forming system, post-cutting, hydraulic station, controlling system, supporter table.

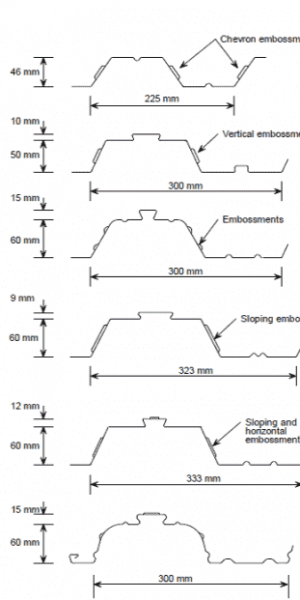

So then, The designing of the metal deck forming machine is aided and optimized by computer. The metal deck produced by this machine has high strength with big wavelength.

Full Automatic Metal Decking Forming Machine

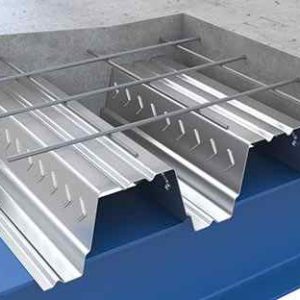

Similarly,The metal roof decking also use in more unusual configurations that may be sloped or curved. Steel decking products are the preferred method of floor construction for multi-story structural steel framed buildings and floor deck offers structural engineers and contractors a versatile and cost-effective composite steel flooring solution.really, decking machine this is the new type we engineer for Roof And Floor Decking Roll Forming Lines, used for building surface panel. The advantages of metal deck roll forming machine are high wave, high strength, high automation, and low cost.

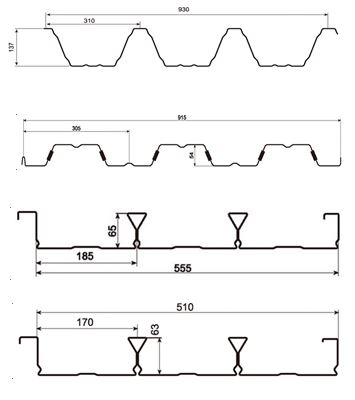

Versa-Dek metal decking Machine

Versa-Dek metal decking is ideal for use in mid-rise residential structures. Dovetail system provides the thinnest total floor depth, reducing story height while maximizing ceiling height, with clear spans up to 28 ft. Versa-Floor is non-combustible and is fire-resistance rated up to four hours without protective coverings such as gypsum and spray-on materials.

Decking Machine

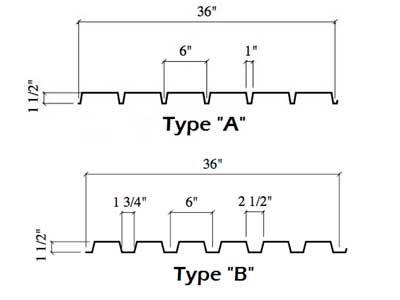

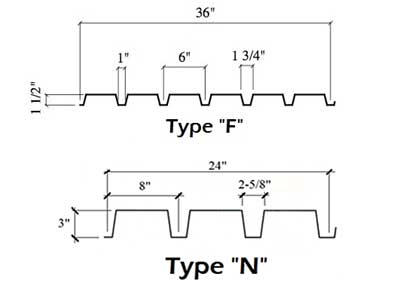

Metal Roof Decks are available in 1-1/2” Deep Type A (narrow rib), Type F (intermediate rib), Type B (wide rib), or 3” Deep Type N (Deep Rib).

Narrow Rib or Type A :

Type A or Narrow Rib Roof Deck is a 1 1/2″ deep, narrow rib, structural metal roof deck section that provides a wide support surface for various types of roofing materials, and thinner rigid insulation.

Wide Rib or Type B :

Type B or Wide Rib Roof Deck is a 1 1/2″ deep, wide rib, structural metal roof deck section that provides a support surface for various types of roofing materials, and 1” or thicker rigid insulation.

Intermediate Rib or Type F :

Type F or Intermediate Rib Roof Deck is a 1 1/2″ deep, intermediate rib metal roof deck that provides an economical roofing system of structural load carrying capacity and roofing insulation materials.

Deep Rib or Type N :

Type N or Deep Rib Roof Deck is a 3″ tall, deep rib metal roof deck, that is designed to provide an economical roofing support surface when longer spans are required between roofing supports.

Technical Proposal

Summary

Material: Steel

Material Thickness: 0.7-1.2mm

Main roll forming machine Power: 15KW*2sets

Motor: Siemens

Forming Speed: 12-13m/min

Machine size: 14000*1700*1500mm

Machine weight: 15000KG

Main Parts

5T Hydraulic Decoiler with cart

Hydraulic feeding table

Hydraulic sheet pre-cutting unit

Roll Forming System

Hydraulic stop cutter

Control system

Output table

Axis Diameter: 85 mm

Pre-cutting unit: Hydraulic way

Forming Roller station: 28 groups

Main Axis material: First grade 45# steel

heated and quenched

Roller material: First grade 45# steel,

Hard Chrome Coated,

heated and quenched

Roller Structure: Heavy-duty casting pillar

Forming Speed: 12-13m/min

Bearing: Japan SKF

Drive Type: Japan CHOHO 1.5’’Chain

Machine Frame stand: 10mm steel welded structure

Cutting Device

Cutting type: Hydraulic Cutter

Cutting system power: 7.5KW

Cutting length tolerance: ±0.05mm

Hydraulic Pump Station

Magnetic valve: HUADE

Cooling system: Winding type

Motor: Siemens

Power: 7.5KW

Electrical System

PLC system: Delta/Panasonic

Touch Screen: Delta/Panasonic

Voltage: 380V/50Hz/3P